Technology

Continuous flow chemistry

Traditionally, all chemical reactions have been carried out in batches. Reagents are added to a reactor, mixed and heated, and, at the end of the process, the product is retrieved. Although widely used, these processes result in inefficiencies and produce significant waste. Recent studies have shown that continuous flow chemistry could significantly decrease production waste. According to the process mass intensification indicator the loss is indeed divided by 10 .

This is why at Fluidichem we chose to embrace the alternative of continuous flow chemistry. This state-of-the-art technology significantly enhances automation capabilities and integrates seamlessly with artificial intelligence, while being environmentally responsible.

In this case, reagents are added continuously to a much smaller reactor and the product is retrieved at the reactor’s outlet. From this reduction in reactor size stem the many advantages of continuous flow chemistry (see diagram below).

Synthesis robot

Continuous flow chemistry lends itself much more to automation than batch chemistry. It is then easier to carry out a large number of reactions more quickly, which facilitates the integration of artificial intelligence.

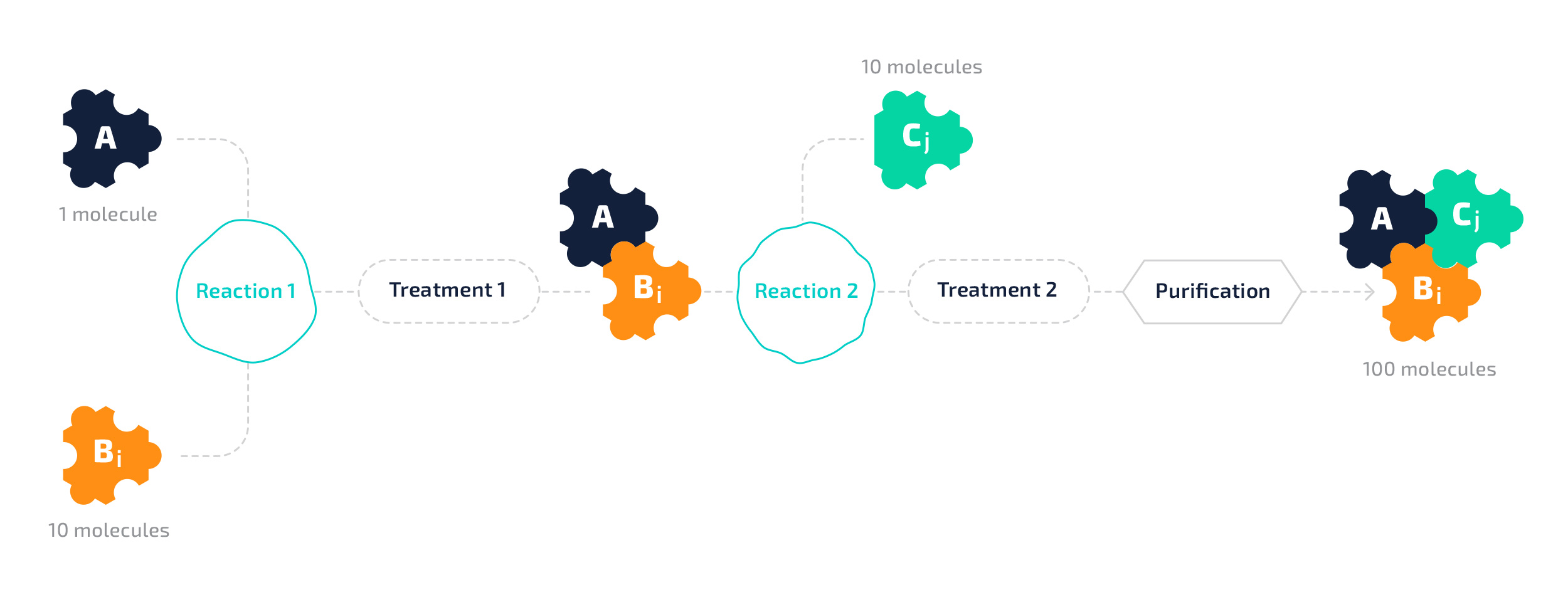

In this context, we developed a synthesis robot, which operates at high speed to produce molecule libraries with unparalleled efficiency, precision and quality. Thanks to AI integration, it rapidly determines optimal synthesis and purification parameters, ensuring a streamlined and intelligent synthesis process. The same robot can be used both to carry out telescoped reactions and to purify the products obtained on a continuous basis (see diagram below).